CTDOT REHABILITATION OF i-395 bridge over route 85

waterFORD, CT

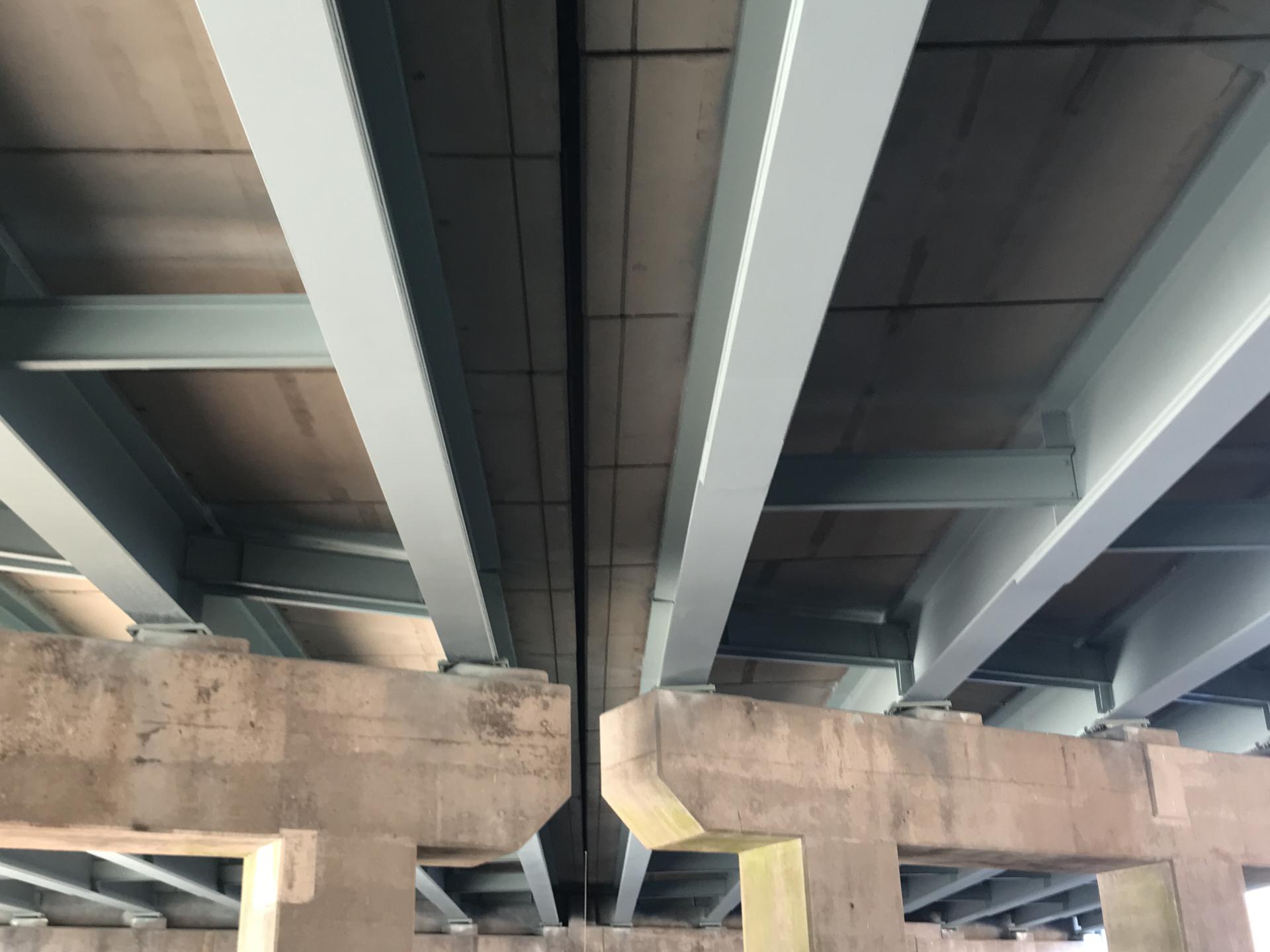

Bridge No. 00255 is a steel beam and concrete deck structure consisting of two spans, with a total length of 182 ft., which carriers Interstate 395 northbound and southbound over Route 85 (Hartford Turnpike), at Exit 77 and a commuter parking lot. The structure was originally constructed in 1955. The superstructure consists of a reinforced concrete deck supported by two simple spans of rolled steel beams with full and partial length cover plates welded to the bottom flange. Each span length is 88 ft. The bridge has a skew angle of 27.28° at each abutment and pier. The overall out-to-out width of both structures together is approximately 104 ft. with fourteen girders in each span, evenly spaced. There are safety walks along each parapet. The substructure consists of reinforced concrete abutments, wingwalls, and a pier. The pier consists of a reinforced concrete pier cap supported by eight reinforced concrete columns. The abutments and wingwalls are supported on spread footings bearing on a rock approximately 25 ft. below grade. The wingwalls are U-type and extend parallel to the road. The existing girders are supported by bronze plate steel bearings with expansion bearings at the abutments and fixed bearings at the pier. The structure is located within a crest vertical curve, with individual curves for each bound.

AIE performed the rehabilitation design of this structure. The proposed rehabilitation consists of replacing the existing 7.5 in. thick reinforced concrete deck with an 8.5 in. thick reinforced concrete precast concrete composite deck for each bound, consisting of 8 ft. wide individual and rectangular shaped precast concrete deck panels, spanning transversely over three girder lines and placed side by side within both spans.

The precast concrete deck panels will be connected by grouted shear keys between the panels and longitudinally post-tensioned along the length of the entire bridge. The precast concrete deck panels over the piers will be non-composite and de-bonded from the top of the girder flanges by placing them on industrial-grade neoprene sheets. The precast concrete deck panels within the positive moment zones in each span will be composite with the girders by engaging them with shear connectors placed inside small pockets within the precast concrete deck panels in each panel. The precast concrete deck panels will be terminated short of the skewed ends at each abutment, to allow space for post-tensioning at each end as well as facilitate the construction of the skewed end slabs after completing the post-tensioning with cast-in-place closure slabs.

There will also be two longitudinal closure pours, one per bound along the entire length of the bridge between panel lines. The existing rolled and 36 in. deep girders with cover plates will remain in place when receiving the new precast concrete deck. The welds at the ends of the cover plates will be peened. The girders and the diaphragms will be fully painted by abrasive blast cleaning and painting with a federal color.

The existing bearings will be replaced with new elastomeric expansion bearings at both the abutments and the pier. As such the entire superstructure will be a floating bridge with no fixed bearings. Keeper-blocks will be constructed at each abutment and the pier to prevent transverse movement and slippage of the superstructure in a seismic event. The substructure will be patched and repaired. The northbound and the southbound superstructures will be separated by a longitudinal joint at the median. Each bound will receive a reinforced concrete parapet along the fascia and a reinforced concrete safety shape median barrier at the median also meeting current standards with a safety shape and separated by a longitudinal joint.

This deck replacement along with the bearing replacement is proposed to be completed in 10 days per bound in conformance with the goals and objectives of Accelerated Bridge Construction (ABC), which state ‘Get-In’, ‘Get-Out’, and ‘Stay-Out’. To achieve this the mainline traffic while replacing each bound will be diverted along adjacent on and off ramps for a period of 10 days. Traffic signals at the bottom of the ramps will be re-timed to coordinate with the ramp and Route 85 traffic during the 10-day period.

Highlights

- Client: CTDOT

- Duration: 2016-2018

- Project Scope:

- Accelerated Bridge Construction (ABC)

- Precast Concrete Deck Panels

- Elastomeric expansion bearings

- Keeper blocks